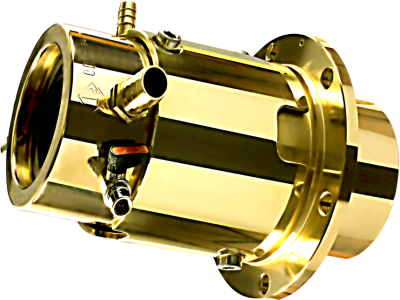

Ts Seal

For rotary shafts

Replace stuffing-boxes and face seals

Industrial and marine applications

EUROPEAN PATENT

n.°0770017

U.S. PATENT

n.°5,795,198

Approval mac/217/94

Approval 09714/AO/ BV

TECHNICAL FEATURES

Self lubricated by biodegradable or edible oil (closed circuit)

Does not need any cooling injection

Can work in absence of fluid level

Allows unlimited axial movements of the rotary shaft

Allows radial and angular misalignments of the rotary shaft

Resistant to aggressive fluids (sludge, sand, marine incrustations…)

100% reliable: slow and gradual wear, no sudden breakdowns

100% watertight: recovery system for any drips

Inflatable seal: allows maintenance during usage

Suitable for marine applications: the unique propeller shaft seal really safe

MARINE APPLICATIONS

Unique Ts Seal features:

You will never need to stop the vessel for breakages and replacement of internal components;

- You can replace the interior oil seals without any rush, as the components have a gradual wear. You may perform this operation when replacing the propeller shaft bearings;

- Even in case of propeller shaft line incidents and even in absence of maintenance, the seal remains safe;

- It does not suffer from sandy waters, marine incrustations, and long stops;

- 100% watertight, no corrosive environment in the bilge, suitable for electric propulsion.

In addition:

Aavailable with inflatable seal (maintenance with the vessel into the water).

Green: lubricated by biodegradable oil to prevent any pollution.

The Ts Seal is used by the leading ship yards (big ships, super yachts, motor yachts..).

INDUSTRIAL APPLICATIONS

The unique technical characteristics of Ts Seal allow to solve problems in many industrial fields (steel industries, paper mills… ).

Our technical department is able to offer a customized solution for each specific application (pressure, fluid, temperature, rpm…).

We also realize special seals for standard ISO pumps.

Ts SEAL WORKING (PATENTED)

Oil circulation, self-aligning bearing, protecting stage

The unique technical characteristics of Ts Seal allow to solve problems in many industrial fields (steel industries, paper mills… ).

Our technical department is able to offer a customized solution for each specific application (pressure, fluid, temperature, rpm…).

We also realize special seals for standard ISO pumps.

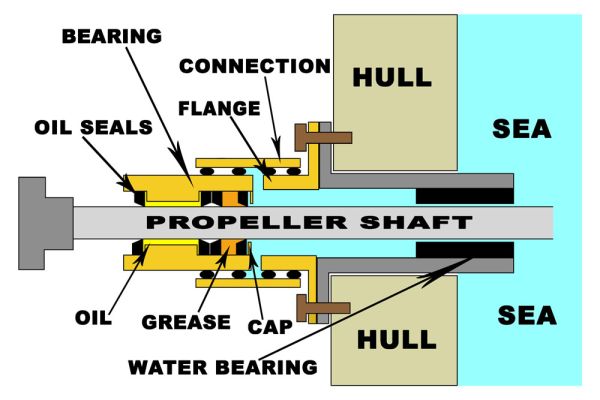

Protecting stage

On the fluid side, the Ts Seal has a patented grease chamber that protects the lip seals from dirty and possible fluid incrustations. A closing cup protects the lip seals from dirt, sand and ropes (marine applications). The fluid pressure prevents the escape of the protecting grease from the Ts Seal.

Easy maintenance

The Ts Seal may be equipped with an inflatable seal on the coupling flange in order to allow the maintenance during use (substitution of the lip seals), without removing the fluid.

Perfect concentricity of the lip seals on the rotary shaft

The interior bearing that houses the lip seals is connected to the coupling flange in a flexible way in order to absorb each misalignment (radial and angular) of the rotary shaft. This guarantees a perfect concentricity of the lip seals on the rotary shaft under any conditions, this concentricity increases considerably the lip seals life. The flexible connection is achieved by a strong coupling joint with double articulation. The strong metal structure of the Ts Seal guarantees a reliable working in every condition, even without oil.

Dynamic lubrication of the lip seals

The interior bearing that contains the lip seals has a special profile which creates an oil pumping with the rotation of the rotary shaft: closed circulation with an external oil reservoir. The oil circulation ensures the creation of an oil film between the shaft and the bearing, as well as near the shaft and the lip seals: that means no friction and excellent durability of the lip seals.